1-09625129-0 ISUZU front hub oil seal TA 85*128*11/21 hub oil seal, Japanese truck parts oil seal

Specification

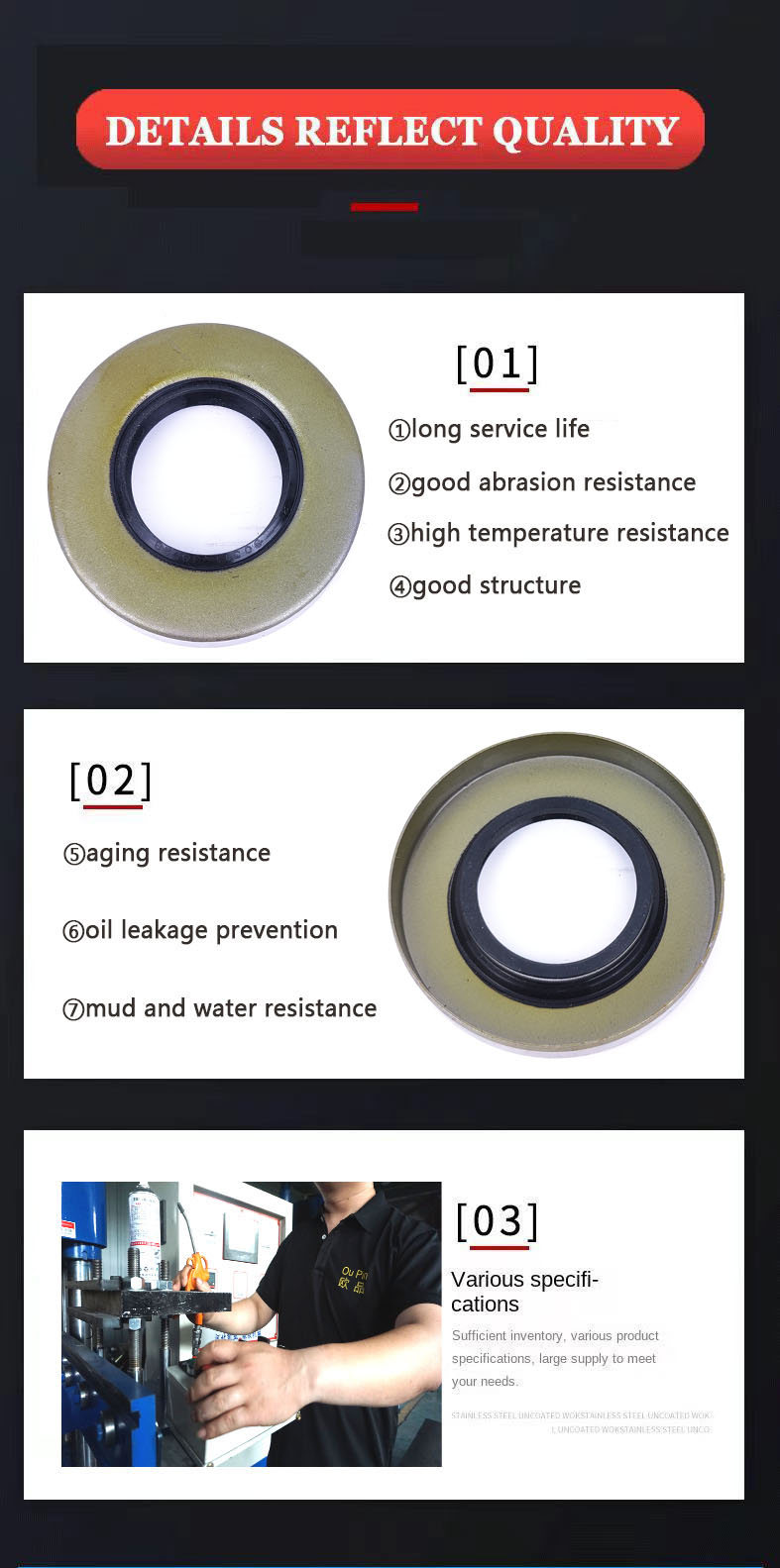

Rubber oil seal

85*128*11/21

Our advantage

● We are specialized in the manufacturing and exporting of high quality seals. Choose us is to choose the rest assured.

● We mainly produces various types, specifications, models of the seals of high precision mechanical components. We have all the specifications of what you need to help you achieve one-stop shopping, save time, effort and worry.

● We has long been a domestic and international numerous oil seal mould supply and product research and development equipment, our research and development ability, is the domestic first-class oil seal manufacturer home.

● We provide one-stop sealing solutions, and provide a full range of services, from product design, mold development, stamping skeleton, vulcanization molding, clip, screening and packaging. The entire process would take a shorter, more stable quality.

Oil seal is not tightly sealed matters needing attention:

1. Master and identify the basic knowledge of fake and inferior products, and choose high-quality and standard oil seals.

2. During installation, if the outer surface roughness of the shaft diameter is low or there are defects such as rust spots, rust, burrs, etc., use a fine emery cloth or oil stone to smooth it; apply clean oil or grease on the oil seal lip or the corresponding position of the shaft diameter. Apply sealant to the outer ring of the oil seal, wrap the keyway on the shaft with hard paper to avoid scratching the lip of the oil seal, and use a special tool to rotate the oil seal inward and press it in. Do not smash hard to prevent the oil seal from being deformed. Or crush the spring and fail; if the lip is flanged, the spring falls off and the oil seal is skewed, it must be removed and re-installed. It should be noted that when the shaft diameter is not worn and the oil seal spring has sufficient elasticity, do not tighten the inner spring [4] without authorization.

3. Oil seals used in machinery are generally subject to harsh working conditions, large environmental temperature differences, a lot of dust, and frequent machine vibrations, which make the mechanical parts constantly changing, and should be inspected, maintained and maintained frequently.

parameter

| product name | Rubber oil seal | ||||||

| OEM | 85*128*11/21 | ||||||

| Material | rubber and steel | ||||||

| color | black | ||||||

| Serve | Sales / After Sales | ||||||

| warranty period | 1 year | ||||||

| Minimum order quantity | 50PCS | ||||||

| Package | Oupin packaging or neutral packaging can also be customized packaging |

||||||

| delivery time | 15-30DAYS | ||||||

| Shipping terms | |||||||

| payment terms | T/T D/P credit card | ||||||

| OEM&ODM: | Custom-made samples are acceptable | ||||||

| material | Low TEMP. |

High TEMP. |

Performance | ||||

| NBR | -40 | 120 | Good resistance to alcohol,amines, petroleum oils, and gasoline over a wide range of temperature. Also good resistance to caustic salts and fair acid. Poor in strong oxidants, chlorinated hydrocarbons, ketones, and esters |

||||

| HNBR | -25 | 140 | HNBR is made from NBR by hydrogenation. It has high temperature resistance, abrasion resistance and good physical properties. |

||||

| ACM | -25 | 150 | It is used in diaphragm, hose for automotive application. Good resistance to heat, ozone and oil. Generally attacked by water, alcohol, glycol and aromatic hydrocarbons. The molecular structure contains ethyl acrylate (EA). Butyl acrylate (BA), and methoxy ethyl acrylate (MEA). High BA content get better low temperature resistance, and high MEA content get more oil resistance. |

||||

| EPDM | -40 | 125 | Stable in polar fluids (alcohol, ketone, and glycol), and hydrochloric acid. Due to the low specific gravity, it can compound with large amount filler. |

||||

| VMQ | -60 | 125 | The most widely temperature ranges for application. Good weather and ozone resistance, but poor mechanical property and chemical resistance. |

||||

| FKM | -20 | 250 | Fluoroelastomers have a high degree of chemical stability and are currently the best media resistance of any elastomer. Type 26 fluoroelastomer resistant to petroleum-based oils, diester oils, silicone ether oils, silicic acid oils, inorganic acids, most organic, inorganic solvents, drugs and so on |

||||